Jun. 08, 2020

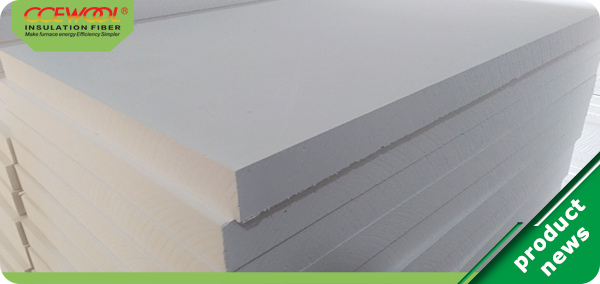

Insulation materials used in glass furnaces should have the lowest possible thermal conductivity. Simply increasing insulation thickness can not compared with the use of materials of low thermal conductivity. The performance of insulation materials used in pool wall insulation, small furnace bottom insulation, feed channel insulation, etc. should be considered first. The performance of insulation calcium silicate board meets the requirements of glass furnaces for thermal insulation.

The advantages of applying calcium silicate board in glass kiln parts are as follows:

1. Feed channel insulation

Traditional insulation calcium silicate board used for feed channel insulation has the disadvantage of being brittle. Generally only one layer of calcium silicate board is stick to the steel shell. High-strength insulation calcium silicate board can be used multiple layers on the steel shell, choose products with temperature resistance of 1200 degrees.

2. Pool wall insulation

Considering the safety and energy saving of the pool wall insulation, if it is made too thick, it will affect the steel structure of the kiln and the installation of the cooling air nozzle, and it is not convenient for hot repair and hot maintenance. The performance of using clay slabs and high-strength insulation calcium silicate board is better than using composite insulation bricks or clay insulation bricks.

Next issue we will continue to introduce advantages of applying insulation calcium silicate board in glass kiln.