Jan. 04, 2021

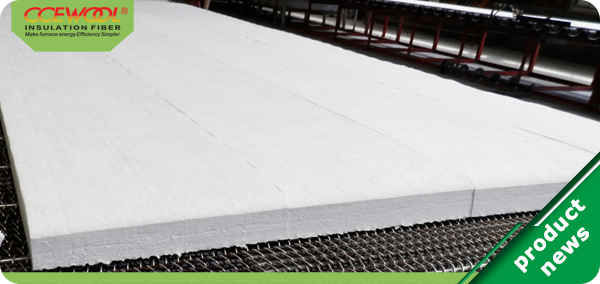

Compared with traditional refractory material refractory insulation fibre products have below advantages.

5. No need for preheating or curing after construction

If furnace is constructed with refractory fire brick or refractory castable, the practical heating up of furnace must be agreed with the planned drying-out curve and curing period of furnace should not be shortened. If the furnace is constructed with refractory castable, the curing period for the furnace will be long, generally 4-7 days, which reduces the utilization rate of the furnace. If the whole furnace lining is ceramic fiber lining and it is not restricted by other metal components, the process temperature of furnace can be quickly raised to required working temperature after construction. It not only improves the effective utilization rate of industrial furnaces, but also reduces non-production fuel consumption.

6. Low thermal conductivity

Refractory insulation fibre products are fiber composites with fiber diameter of 3-5um. They have many voids and very low thermal conductivity. However, at different temperatures, their lowest thermal conductivity has a corresponding optimal bulk density, and their lowest thermal conductivity and corresponding bulk density increase with the increase of temperature. According to the experience of applying full fiber structure cracking furnace in recent years, the best density of fiber lining should be controlled at 200~220 kg/m3.

7. It has better chemical stability and resistance to airflow erosion

Refractory insulation fibre products are only corroded in phosphoric acid, hydrofluoric acid and hot alkali, and are stable to other corrosive media.