Aug. 24, 2020

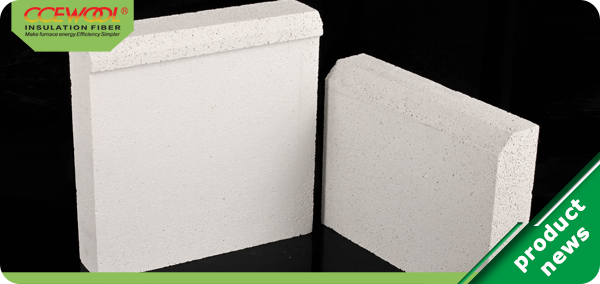

Production process principle of CCEFIRE insulation mullite brick.

Kyanite is the main raw material, and a small amount of industrial alumina is added to produce insulation mullite brick. The raw materials must be finely ground, and the ground materials particles should be below 20 microns. In such a fine particle state, part of the industrial alumina already has a colloidal size, and the mud has good suspension. The ground mud is filtered through a mud filter into a mud cake, and plastic clay and chemical plasticizers can be added to improve plasticity and adhesion. Add organic matter such as polystyrene pellets to the made mud cake according to the design of the lightweight brick, and then mix the material with a strong mixer. After mixing, the material will be stayed still for 24 hours, and the vacuum extruder will be used for vacuum extrusion. After forming, the wet body is dried, and then fired at a high temperature of 1550°C for 5 hours.

Characteristics and application of CCEFIRE insulation mullite brick

The insulation mullite brick with kyanite as the main raw material has the characteristics of high service temperature, low conductivity, small heat capacity, high strength, and excellent thermal shock resistance. It is mainly used in various kilns of daily porcelain, building ceramics and special industrial ceramics, and high temperature kilns in the petrochemical industry, high-end heating furnaces and hot blast furnaces in the metallurgical industry, etc. Its long term working temperature is above 1600 degrees.